About Auer Signal

We build on traditional Austrian engineering skills

Our production site and headquarters are located in the south of Vienna. We employ about 150 people. Both development and production take place 100% in Austria. Signaling devices from Auer Signal come from a single source, from the initial idea to design, development and production. We are very proud of our company's commitment to the Austrian economy and to the traditional art of Austrian engineering. At the same time we take pride in providing our products to customers on a global basis.

Signaling devices made in Austria

From planning and construction to a diverse range of measuring and testing procedures and right up to production, signaling devices from Auer Signal are an example of the highest level of engineering and quality.

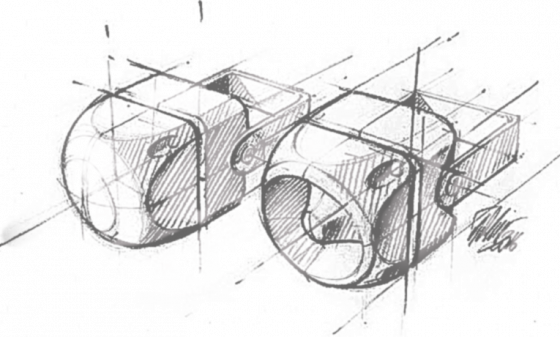

Planning and construction

Herbert von Karajan,

Austrian conductor

We are convinced that the form of a piece of signaling equipment cannot be separated from its technical purpose. When planning a new product, we place great importance on the design language

and the product design.

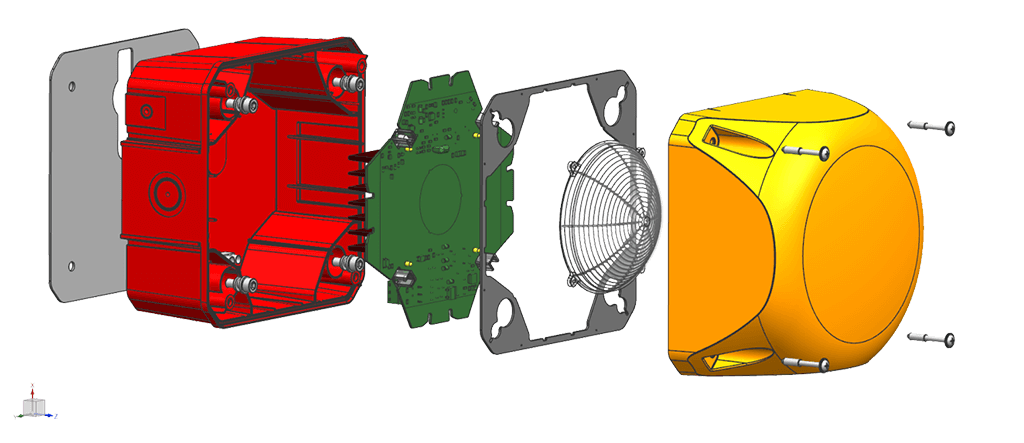

3D Engineering

At Auer Signal, planning and designing are carried out with the latest and most innovative 3D tools.

This is especially important, as it allows our construction department to identify and resolve construction faults at an early stage. This puts us one step ahead in terms of speed of implementation and product quality.

Digital Prototyping

Digital prototyping enables our engineers and designers to run virtual tests on their 3D designs before putting them into practice.

Digital prototyping enables our development teams to test and optimise 3D CAD designs, in order to drive innovation, ensure the best quality and shorten product launch times.

Digital simulation in combination with the latest testing procedures is an essential part of the development process of a high-tech company such as Auer Signal.

Testing,

only the strong survive

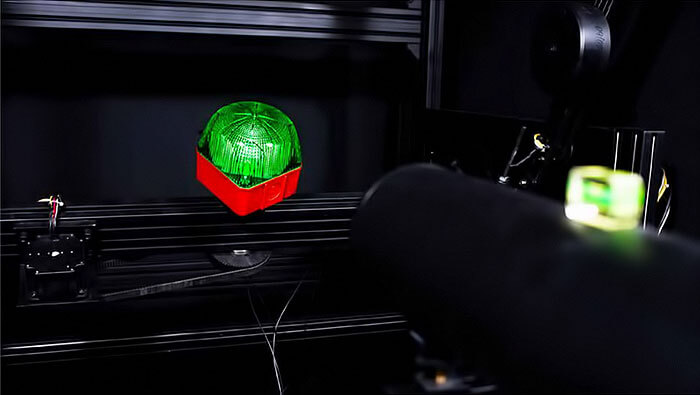

Before a new signaling device goes into series production, it must undergo and pass numerous complex measuring procedures.

During the measuring procedures, the new product from Auer Signal must demonstrate what our development engineers promised during digital prototyping.

Visual measuring procedures

The luminous intensity and the luminance distribution are measured from different viewing angles using a photogoniometer. This test demonstrates the light distribution and luminous intensity of our beacons.

Audible measuring procedures

All audible signaling equipment is tested in our own measuring rooms. We can create perfect free field conditions in these measuring rooms. This enables us to measure the sound pressure of our audible signaling equipment precisely. Along with the sound pressure, the

frequency response is also extremely important. It describes the sound pressure at a certain frequency. This information helps to select the right audible signaling equipment for the relevant application.

Mechanical test procedures

The behaviour of the materials and the signaling equipment is put to the test in various mechanical tests. During what is known as conditioning, the product is subjected to extreme loads: Depending on the specification, the signaling device must be impact-resistant, water-tight and dust-proof. If required, signaling devices from Auer Signal must withstand extreme cold, heat and temperature fluctuations.

()

()